Cabinet Doors Product Guide

See our full cabinet doors product guide, including specifications, tolerances, and profile options.

Product Guide Contents

- Cabinet Doors Overview

- Door Wood Types

- Door Construction Types

- Door Thickness Options

- Door Rail and Stile Widths

- Framing Bead Profiles: 5-Piece (5pc)

- Framing Bead Profiles: MDF (2pc & 1pc)

- Center Panel Profiles: MDF

- Center Panel Profiles: MDF Plywood with Veneer

- Center Panel Profiles: Solid Wood

- Outside Edge Profiles

- Glass Frames and Mullions

- Hinge Boring Options (Hinge Holes)

- Cabinet Door Hinge Sides

- Cabinet Door Hinges Available

- Door Finish Options

- Center Panel Wood Grain Direction

- Door Size Specifications and Tolerances

- Effects of Moisture in Wood

Cabinet Doors Overview

Eagle Woodworking provides a series of pre-built door styles that customers may select. These are the most common door style types and come with pre-set options. Customers may select a style and then adjust the pre-set options to create a custom door.

Full customization options are also available by selecting style ‘Custom’ on our online order form, which allows the customer to build the door options to exact specifications. Our pdf order form does not include pre-set door styles as options; however all the various options are available on the pdf form.

If a customer has a custom request outside of the scope of the options provided in this product guide, the customer can make that request by adding ‘Notes’ to an online order or emailing doors@eagledovetaildrawers.com outlining the request.

Door Wood Types

Our custom cabinet doors and drawer fronts are crafted using only the finest hardwoods, selected from the nation’s best lumber mills. MDF doors are crafted from high-quality fiberboard, subject to a rigorous double refining process for unmatched durability, stability, and moisture resistance.

Eagle Woodworking keeps the following standard wood and material types in stock at 3/4" thickness only.

- Maple – paint grade

- Maple

- White Oak

- MDF

Requests for wood types and thicknesses not listed above are available but may require longer than standard lead times. Other wood types include:

- Birch

- Birch – paint grade

- Walnut

- Red Oak

- Cherry

Door Construction Types

Eagle Woodworking offers the following standard door construction types:

- 5-piece solid hardwood

- 2-Piece MDF

- 1-Piece MDF

- Slab (hardwood and MDF)

Door Thickness Options

Eagle Woodworking keeps the following standard wood thicknesses in stock:

- 3/4" (default)

Requests for thicknesses not listed above may be accommodated but may require longer than standard lead times. Other thicknesses include:

- 7/8"

- 1"

Door Rail and Stile Widths

Eagle Woodworking offers the following standard rail and stile widths:

'5pc - Bar Harbor' & '1pc - Monroe' framing beads only

- 1/2"

- 3/4"

- 1” (default)

All other framing bead profiles

- 1-1/2"

- 1-3/4"

- 2-1/4" (default)

- 2-1/2"

- 3”

- 3-1/4"

Requests for widths not listed above may also be accommodated by special request. Rail and Stile widths are inclusive of framing bead profiles.

Door Width Minimums – when the door width is below certain thresholds for a stile thickness, the stile thickness will be reduced to accommodate the center panel. Below are the different configurations which will result in a reduction of stile thickness.

| Door Stile Thickness | Minimum Door Width | Reduced Stile Thickness |

| 1-1/2" | 7" | Slab |

| 1-3/4" | 7-1/2" | Slab |

| 2-1/4" | 8-1/2" | 1-1/2" |

| 2-1/2" | 9" | 1-1/2" |

| 3" | 10" | 2-1/4" |

| 3-1/4" | 10-1/2" | 2-1/4" |

Ex: If the door is constructed using a 2 1/4" stile thickness, then the minimum door width available is 8 1/2”. If the customer requests an 8” door width, then the stile thickness will be reduced to 1 3/4”. If the customer requests a 7” door width, then the door construction will be adjusted to a slab.

Door Height Minimums – when the door height is below certain thresholds for a rail thickness, the rail thickness will be reduced to accommodate the center panel. Below are the different configurations which will result in a reduction of rail thickness:

| Door Rail Thickness | Minimum Door Height | Reduced Rail Thickness |

| 1" | 3-3/4" | Slab |

| 1-1/2" | 4-3/4" | Slab |

| 1-3/4" | 5-1/4" | Slab |

| 2-1/4" | 6-1/4" | 1-1/2" |

| 2-1/2" | 6-3/4" | 1-1/2" |

| 3" | 7-3/4" | 2-1/4" |

| 3-1/4" | 8-1/4" | 2-1/4" |

Ex: If the door is constructed using a 2 1/4" rail thickness, then the minimum door height available is 6 1/4”. If the customer requests a 6” door width, then the rail thickness will be reduced to 1 3/4”. If the customer requests a 5” door width, then the door construction will be adjusted to a slab.

5-Piece (5pc) Framing Bead Profiles

5-Piece framing beads (inside profile) are available for all wood doors.

|

|

|

5pc – A (Style: Boston Shaker) |

5pc – B (Style: Providence) |

|

|

|

5pc – C (Style: Hartford) |

5pc – D (Style: Portsmouth) |

|

|

|

5pc – F (Style: Manchester) |

5pc – G (Style: Newport Ogee) |

|

|

|

5pc – I (Style: Portland) |

5pc – P (Style: Bar Harbor) *Slim shaker mitered construction |

*Beveled edges to create shadow lines are available upon request.

MDF Framing Bead Profiles 2-Piece (2pc) and 1-Piece (1pc)

|

2-Piece (2pc) Profiles |

1-Piece (1pc) Profiles |

|

|

|

2pc – A (Style: Jefferson Shaker) |

1pc – A (Style: Jefferson Shaker) |

|

|

|

2pc – B (Style: Monroe Slim Shaker) |

1pc – B (Style: Monroe Slim Shaker) |

|

|

|

2pc – C (Style: Adams) |

1pc – C (Style: Adams) |

|

|

|

2pc – D (Style: Franklin) |

1pc – D (Style: Franklin) |

|

|

|

2pc – E (Style: Washington) |

1pc – E (Style: Washington) |

|

|

|

2pc – F (Hamilton) |

1pc – F (Style: Hamilton) |

|

|

|

2pc – G (Madison Ogee) |

1pc- G (Madison Ogee) |

MDF Center Panel Profiles

The default material for center panels is MDF.

|

|

|

MDF-01 flat front panel with 1/8" back reveal

|

MDF-02 3/8" flat panel default 2pc MDF *only available with 2-Piece MDF or framing bead 5pc - P (Bar Harbor) |

|

|

|

|

MDF-03 beveled raised panel |

MDF-04 ogee raised panel |

|

|

|

MDF-05 cove raised panel |

MDF-06 beveled raised panel with shelf |

|

|

|

MDF-07 1/4" flat panel default 5pc painted |

MDF-08 reverse bevel |

|

|

|

|

MDF-09 reverse cove |

|

MDF Plywood with Veneer Center Panel Profiles

MDF plywood with veneer center panels are the default for stained doors, typically walnut and white oak, where the customer intends to spray a clear stain on the door instead of paint.

|

|

|

VNR-01 1/4" veneer flat panel default 5pc stained |

VNR-02 3/8" veneer flat panel *only available with framing bead 5pc - P (Bar Harbor) |

|

|

|

|

VNR-03 veneer flat front panel with 1/8" back reveal |

|

Solid Wood Center Panel Profiles

|

|

|

WD-01 flat front panel with 1/8" back reveal |

WD-02 3/8" flat panel *only available with framing bead 5pc - P (Bar Harbor) |

|

|

|

WD-03 beveled raised panel |

WD-04 ogee raised panel |

|

|

|

WD-05 cove raised panel |

WD-06 colonial raised panel |

Outside Edge Profiles

On the default option, all edges are hand broken, ideal for finishing.

|

|

|

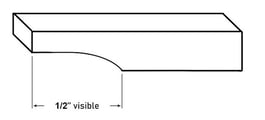

E-01 hand broken with 1/16" round over default |

E-02 ogee edge |

|

|

|

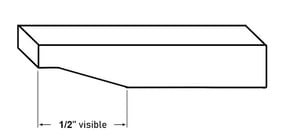

E-03 1/4" beveled edge |

|

Glass Frames and Mullions

Eagle Woodworking provides the following cuts for glass frames and mullion doors. When placing an order that includes glass doors, customers should select the desired style, including center panel for any doors or drawer fronts that will not include glass tiles, as well as selecting the desired number of tiles for mullions in the door type drop down on the order form.

Glass door mullions are 3/4" wide.

Mullion Construction - we use glue at each joint, then further secure the joints with a crown stable. Those staples are visible from the back of the door. We do our best to sink the staples so they are flush with the wood, but depending on the material, sometimes the staples are slightly proud of the material. See a video example of our mullions here.

Routing for glass retainer strips can be completed on most frame and mullion styles. Clear retainer strips will be provided for any glass doors.

The formulas for determining the size of glass panels is as follows:

Glass Width = Door Width - 2 x Stile Width + 2.5

Glass Height = Door Height - 2 x Rail Width + 2.5

*This provides the exact measurement; it is recommended for customers to add a slight deduction (1/16") to add space for easy insertion.

Hinge Boring Options (Hinge Holes)

Our standard hole placement for hinge holes is 3" from the top and bottom edge of the cabinet door.

The standard depth for hinge boring is 13mm. We do not offer custom hinge boring depths.

The table below outlines our standard hinge hole placements based on cabinet door height.

| Door Height | # of holes | Hole Placement - MDF | Hole Placement - Wood |

| Less than 9" | 0 | N/A | N/A |

| 9" to 39" | 2 | 3" from top and bottom edge | 3" from top and bottom edge |

| 39-1/6" to 60" | 3 | 3" from top and bottom edge with 1 hole centered | 3" from top and bottom edge with 1 hole centered |

| 60-1/16" to 80" | 4 | 3" from top and bottom edge with holes evenly spaced | 3" from top and bottom edge with 2 holes 22" from each end |

| Greater than 80" | 5 | 3" from top and bottom edge with holes evenly spaced | 3" from top and bottom edge with 2 holes at 22" from each end and 1 hole centered |

Eagle Woodworking offers the following standard hinge boring options:

|

|

|

A-03 cup only 3mm tab distance (1/8") |

A-05 cup only 5mm tab distance (3/16") |

|

|

|

B-03 cup & dowell 3mm tab distance (1/8") |

B-05 cup & dowell 5mm tab distance (3/16") |

Cabinet Door Hinge Sides

If requesting hinge boring on a specific side of the door (left or right), please specify 'left' or 'right' as you face the front of the door.

Cabinet Door Hinges Available

Eagle Woodworking offers the following cabinet door hinges:

- Coming Soon

Door Finish Options

All doors and drawer fronts are sanded prior. Sanding is not applied after a single prime coat but is applied between coats and after on a prime double coat.

Eagle Woodworking offers the following finish options:

- None (default)

- Prime - single coat

- Prime - double coat

Center Panel Wood Grain Direction

Our default wood grain direction on center panels is vertical for cabinet doors and horizontal for drawer fronts.

Door Size Specifications and Tolerances

-

Eagle Woodworking manufactures all wood products to the nearest 1/16" or 1.6mm, allowing for a tolerance of +/-1/32" or +/-0.8mm.

-

Doors ordered over 50” tall will include a center rail unless specified by customer. Eagle Woodworking will not warranty doors greater than 50” tall without a center rail.

- The maximum height or width for MDF doors is 96". There is no maximum height or width for wood doors.

-

The allowable tolerances for bow, warp, or twist in different types of doors (5-piece and 2-piece MDF) are as follows:

-

Single panel doors up to 26" wide and 48" high: 1/8" tolerance.

-

Multi-panel doors up to 26" wide and 48" to 65" high: 1/4" tolerance.

-

Multi-panel doors up to 26" wide and 65" to 84" high: 5/16" tolerance.

-

Single panel, single opening frame-only, and mullion doors exceeding 26" wide and 48" high are not warranted (mullion lites are excluded from the opening count).

-

Doors that are wider than 26" or taller than 84" will not be warrantied.

-

-

The allowable tolerances for bow, warp, or twist in different types of doors (1-piece MDF) are as follows:

-

Up to 12" wide and 22" high = 1/8".

-

12" to 22" wide or 22" to 44" high = 1/4".

-

Any one-piece product exceeding 22" wide or 44" high will not be warrantied.

-

Effects of Moisture in Wood

- Solid wood products are prone to expansion and contraction as moisture and climate conditions fluctuate over time. Stable moisture levels are crucial for maintaining tight joints.

- Moisture changes can lead to effects such as panel expansion, panel contraction, joint expansion or opening (especially in miter doors), bowing of stiles, stile and rail expansion, and visible stave-to-stave lines in panels. Contraction in finished panels may also cause a "white line" effect, where a narrow strip of unfinished wood appears where the panel meets the framing.

- Wood products in humid climates are particularly vulnerable to expansion due to moisture. Eagle Woodworking does not warranty against product failure resulting from excessively humid conditions, including in waterfront properties and coastal regions.

- Environments such as indoor pools or marine applications, including nautical vessels, are considered high-humidity areas regardless of any climate control systems present.

- In contrast, wood products in dry climates are more susceptible to contraction due to low moisture levels in the air. Eagle Woodworking will not warranty against product failure caused by excessively dry conditions, such as those found in desert and mountain regions.

- Installing cabinetry in new construction before climate control is activated can cause the wood to absorb moisture from other building materials like paint, drywall compound, concrete, stucco, and wood framing with high moisture content. These materials release significant amounts of moisture during the drying/curing process.

- Wood products installed in non-air-conditioned homes, regardless of location, are highly prone to moisture-induced expansion and will not be warrantied. Stable moisture conditions are essential for all wood products to keep joints tight.

- To reduce moisture-related expansion, secondary and vacation homes should maintain some form of climate control, even during the off-season. Eagle Woodworking does not warranty products installed in environments lacking climate control.

Ordering Online is Easy

You can order custom drawers and doors directly through our online form. Simply put in your information, add any necessary details — like a job number —, select your delivery option, and then choose specifics like wood species and thickness. If it sounds simple, that’s because it is.